Selecting the right paver block making machine is crucial for any construction or manufacturing business looking to produce high-quality pavers efficiently. With numerous options available in the market, it's important to carefully consider various factors to ensure you invest in a machine that meets your specific needs and delivers optimal performance. This comprehensive guide will walk you through the key considerations when choosing a paver block making machine, helping you make an informed decision for your business.

Understanding Your Production Requirements

Before diving into the specifics of different machines, it's essential to assess your production needs:

1. Production Capacity: Determine the volume of paver blocks you need to produce daily or monthly. This will help you choose a machine with the appropriate output capacity.

2. Types of Pavers: Consider the variety of paver shapes, sizes, and designs you plan to manufacture. Some machines offer more versatility than others.

3. Available Space: Evaluate the space you have for the machine and its accompanying equipment. Ensure you have enough room for operation, maintenance, and storage.

4. Budget: Establish a realistic budget that accounts for not just the initial purchase cost, but also long-term operational and maintenance expenses.

Key Features to Look for in a Paver Block Making Machine

When evaluating different paver block making machine options, pay attention to these critical features:

1. Hydraulic System

A robust hydraulic system is the heart of any efficient paver block making machine. Look for machines with:

- High-quality hydraulic components from reputable manufacturers

- Adequate hydraulic pressure for consistent and powerful block formation

- Smooth operation with minimal vibration

- Easy maintenance and accessibility of hydraulic parts

2. Mold System

The mold system directly impacts the quality and variety of pavers you can produce:

- Check the range of mold options available for the machine

- Assess the ease of mold changes and adjustments

- Look for machines with durable, precision-engineered molds

- Consider machines that offer customizable mold options

3. Vibration System

Proper vibration ensures uniform compaction and density of paver blocks:

- Evaluate the vibration frequency and amplitude

- Look for machines with adjustable vibration settings

- Consider systems with anti-vibration features to reduce operator fatigue

4. Control Panel and Automation

Modern paver block making machines often come with advanced control systems:

- User-friendly interface for easy operation

- Programmable settings for different paver types

- Automated cycle control for consistent production

- Real-time monitoring and diagnostics capabilities

5. Material Feeding System

An efficient feeding system ensures smooth and continuous production:

- Look for machines with adequate hopper capacity

- Consider options with automated material feeding

- Evaluate the ease of cleaning and maintenance of the feeding system

6. Compaction Mechanism

The compaction process is crucial for producing high-quality, durable pavers:

- Assess the compaction force and adjustability

- Look for machines with uniform compaction across the mold

- Consider options with multi-stage compaction for enhanced density

7. Safety Features

Prioritize machines with robust safety measures:

- Emergency stop buttons

- Safety guards and interlocks

- Noise reduction features

- Dust control systems

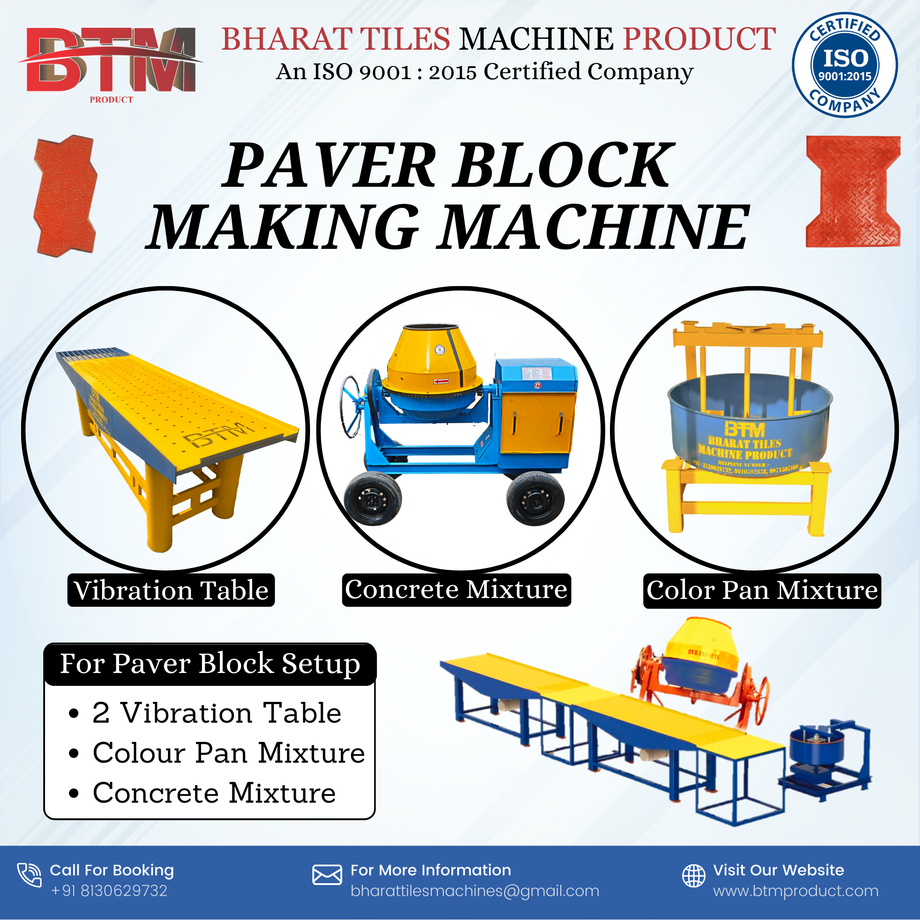

Our Other Machines

interlocking tiles making machine

Evaluating Machine Manufacturers

When choosing a paver block making machine, it's not just about the equipment itself, but also the company behind it. Consider these factors when evaluating manufacturers:

1. Reputation and Experience

Research the manufacturer's track record in the industry. Companies like BTM Product have established themselves as reliable providers of quality paver block making machines. Look for:

- Years of experience in manufacturing concrete equipment

- Positive customer reviews and testimonials

- Industry recognition and certifications

2. After-Sales Support

Reliable after-sales service is crucial for maintaining your paver block making machine's performance:

- Availability of spare parts and consumables

- Responsive technical support

- Comprehensive warranty coverage

- Training programs for operators

3. Technology and Innovation

Choose a manufacturer that invests in research and development:

- Regular updates and improvements to their machine designs

- Integration of new technologies for enhanced efficiency

- Commitment to sustainability and energy efficiency

4. Customization Options

Every business has unique requirements. Look for manufacturers willing to tailor their machines to your specific needs:

- Ability to modify machine specifications

- Options for custom mold designs

- Flexibility in production line configuration

Considering Long-Term Costs

While the initial purchase price is important, it's equally crucial to consider the long-term costs associated with owning and operating a paver block making machine:

1. Energy Efficiency

- Compare the power consumption of different models

- Look for machines with energy-saving features

- Consider options with variable speed drives for optimized energy use

2. Maintenance Requirements

- Evaluate the frequency and complexity of required maintenance

- Consider the availability and cost of spare parts

- Look for machines with easy-to-access components for simpler maintenance

3. Durability and Lifespan

- Assess the build quality and materials used in construction

- Look for machines with corrosion-resistant components

- Consider the expected lifespan of the machine and its major components

4. Upgradability

- Choose a machine that allows for future upgrades or modifications

- Consider the compatibility with additional equipment for expanded production capabilities

Making the Final Decision

After carefully evaluating all the factors mentioned above, it's time to make your final decision. Here are some additional tips to help you choose the best paver block making machine for your business:

1. Request Demonstrations

Ask manufacturers or dealers for live demonstrations of their machines. This will give you a firsthand look at the machine's operation and performance.

2. Consult with Experts

Seek advice from industry professionals or consultants who have experience with various paver block making machines. Their insights can be invaluable in making an informed decision.

3. Visit Reference Sites

If possible, visit businesses that are using the machines you're considering. This will give you a realistic view of how the machine performs in a production environment.

4. Consider Future Growth

Choose a machine that not only meets your current needs but also has the capacity to accommodate future growth in your business.

5. Analyze Return on Investment

Calculate the potential return on investment for each machine option, considering factors like production capacity, operational costs, and expected lifespan.

Some Blogs

Automatic Fly Ash Brick Making Machine at the Best Price

Get the Best Fly Ash Brick Making Machine in India

Conclusion

Choosing the best paver block making machine is a significant decision that requires careful consideration of numerous factors. By thoroughly evaluating your production requirements, key machine features, manufacturer reputation, and long-term costs, you can make an informed choice that will benefit your business for years to come.

Remember that while price is an important factor, it shouldn't be the sole determining factor. Investing in a high-quality paver block making machine from a reputable manufacturer like BTM Product can lead to improved efficiency, higher-quality products, and better long-term value for your business.

Take the time to research, compare options, and consult with experts before making your final decision. With the right paver block making machine, you'll be well-equipped to meet the growing demand for high-quality pavers in the construction industry.