Are you looking to expand your construction business or start a new venture in the brick manufacturing industry? A fly ash brick making machine could be the perfect investment for you. In this comprehensive guide, we'll explore everything you need to know about these innovative machines and how they can benefit your business.

What is a Fly Ash Brick Making Machine?

A fly ash brick making machine is a specialized piece of equipment designed to produce bricks using fly ash, a byproduct of coal combustion, as the primary raw material. These machines offer an eco-friendly alternative to traditional clay brick production, utilizing industrial waste to create durable and cost-effective building materials.

Benefits of Investing in a Fly Ash Brick Making Machine

1. Environmental Sustainability

By using fly ash, a waste product from thermal power plants, these machines help reduce the environmental impact of brick production. This eco-friendly approach aligns with growing demand for sustainable construction materials.

2. Cost-Effectiveness

Fly ash bricks are generally cheaper to produce than traditional clay bricks, thanks to the availability of raw materials and efficient production processes. This can lead to significant cost savings for your business.

3. High Production Capacity

Modern fly ash brick making machines can produce thousands of bricks per day, allowing you to meet high demand and scale your business quickly.

4. Consistent Quality

These machines ensure uniform brick quality, resulting in stronger and more durable bricks compared to manually produced alternatives.

5. Versatility

Fly ash brick making machines can produce various types of bricks, including solid bricks, hollow bricks, and interlocking bricks, catering to different construction needs.

Our Other Machines

interlocking tiles making machine

paver block making machine

Choosing the Right Fly Ash Brick Making Machine for Your Business

When selecting a fly ash brick making machine, consider the following factors:

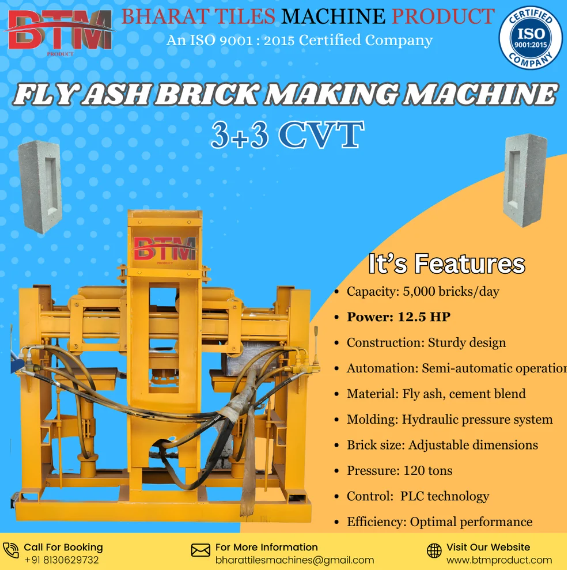

Production Capacity

Determine your required output based on market demand and your business goals. BTM Product offers machines with varying production capacities to suit different needs.

Automation Level

Choose between fully automatic, semi-automatic, or manual machines based on your budget and workforce availability. Fully automatic machines from BTM Product offer the highest efficiency and require minimal human intervention.

Quality and Durability

Invest in a high-quality machine that can withstand continuous operation and produce consistent results. BTM Product's machines are known for their robust construction and reliability.

Energy Efficiency

Look for machines with energy-saving features to reduce operating costs and improve your bottom line. BTM Product incorporates the latest energy-efficient technologies in their fly ash brick making machines.

After-Sales Support

Ensure the manufacturer provides comprehensive after-sales support, including installation, training, and maintenance services. BTM Product offers excellent customer support to keep your machine running smoothly.

Key Features to Look for in a Fly Ash Brick Making Machine

1. Hydraulic System

A powerful hydraulic system ensures consistent pressure and uniform brick quality. BTM Product's machines feature advanced hydraulic systems for optimal performance.

2. Vibration Mechanism

Efficient vibration helps in proper compaction of the raw materials, resulting in stronger bricks. Look for machines with adjustable vibration settings.

3. Mold Customization

The ability to change molds allows you to produce different brick sizes and shapes. BTM Product offers a wide range of mold options for versatility.

4. Control Panel

An user-friendly control panel with digital displays makes it easy to monitor and adjust machine parameters. BTM Product's machines come with intuitive control systems for seamless operation.

5. Safety Features

Ensure the machine has adequate safety measures, such as emergency stop buttons and protective covers. BTM Product prioritizes operator safety in their machine designs.

Raw Materials and Mix Design

To produce high-quality fly ash bricks, you'll need the right mix of raw materials. The typical composition includes:

- Fly ash (50-60%)

- Sand or stone dust (30-35%)

- Lime (8-10%)

- Gypsum (1-2%)

BTM Product can provide guidance on optimizing your mix design for the best results with their fly ash brick making machines.

Some Blogs

Automatic Fly Ash Brick Making Machine at the Best Price

Get the Best Fly Ash Brick Making Machine in India

Setting Up Your Fly Ash Brick Production Plant

1. Site Selection

Choose a location with easy access to raw materials and transportation routes. Consider factors like land cost, availability of utilities, and local regulations.

2. Plant Layout

Design an efficient plant layout that allows for smooth material flow and maximizes productivity. BTM Product can assist with layout planning based on your specific requirements.

3. Equipment Installation

Proper installation of your fly ash brick making machine is crucial for optimal performance. BTM Product offers professional installation services to ensure your machine is set up correctly.

4. Training and Skill Development

Invest in training your staff to operate and maintain the machine effectively. BTM Product provides comprehensive training programs for operators and maintenance personnel.

Maintenance and Troubleshooting

Regular maintenance is essential to keep your fly ash brick making machine running smoothly and extend its lifespan. Some key maintenance tasks include:

- Daily cleaning of the machine and molds

- Regular lubrication of moving parts

- Inspection and replacement of wear parts

- Calibration of sensors and control systems

BTM Product offers maintenance packages and readily available spare parts to minimize downtime and keep your production on track.

Marketing Your Fly Ash Bricks

To maximize the return on your investment in a fly ash brick making machine, consider these marketing strategies:

1. Highlight Environmental Benefits

Promote the eco-friendly nature of fly ash bricks to appeal to environmentally conscious customers and projects.

2. Emphasize Cost Savings

Showcase the cost-effectiveness of fly ash bricks compared to traditional clay bricks.

3. Demonstrate Quality and Durability

Provide test results and certifications to prove the strength and durability of your bricks.

4. Target Green Building Projects

Reach out to architects and developers involved in green building initiatives and LEED-certified projects.

5. Offer Custom Solutions

Leverage the versatility of your fly ash brick making machine to produce custom brick sizes and shapes for specific projects.

Future Trends in Fly Ash Brick Production

The fly ash brick industry is continually evolving, with new technologies and innovations emerging. Some future trends to watch out for include:

- Integration of IoT and AI for predictive maintenance and quality control

- Development of new additives to further enhance brick properties

- Increased automation and robotics in brick production and handling

- Research into using other industrial waste materials in brick production

BTM Product stays at the forefront of these developments, continuously improving their fly ash brick making machines to meet evolving industry needs.

Conclusion

Investing in a high-quality fly ash brick making machine can be a game-changer for your construction or brick manufacturing business. With its eco-friendly approach, cost-effectiveness, and high production capacity, this technology offers numerous advantages over traditional brick-making methods.

By carefully considering your business needs and choosing a reputable manufacturer like BTM Product, you can find the perfect fly ash brick making machine to drive your success. Remember to focus on factors such as production capacity, automation level, energy efficiency, and after-sales support when making your decision.

As the construction industry continues to embrace sustainable practices, the demand for fly ash bricks is likely to grow. By positioning your business at the forefront of this trend with a state-of-the-art fly ash brick making machine, you'll be well-equipped to meet market demands and contribute to a greener future in construction.

Take the next step towards revolutionizing your brick production process. Explore BTM Product's range of fly ash brick making machines and find the perfect solution for your business today.